The “Internet of Things” (IoT), or more specifically the “Industrial Internet of Things” (IIoT) has rapidly evolved since 2010, in large part parallel to the evolution of a new generation of MEMS based sensor technology (MEMS: Micro-Electro-Mechanical Systems). The evolution of this technology and ever-improving communication platforms is truly transformational in how industrial and manufacturing clients approach to managing and optimizing use of their equipment. Hence, Iot Condition Based Maintenance (IoT-CBM) or Iot Machine Condition Monitoring (IoT-MCM), and more specifically, the concept of CAMP-CBM / CAMP-MCM systems.

On of the most important variables in industrial economics revolve around determining the condition of machines and mechanical systems in order to optimize their availability, reliability and costs. Traditionally this has been almost prohibitively expensive for not just the smaller industries, but also the industrial giants. So much so, that even the most successful industrial sites have had to divide the monitoring and management of machines/equipment and system based on the criticality of those. Thus the term Balance-of-plant (BOP) evolved to describe those machines and equipment that are peripheral to the most vital and most critical productions systems. Because of cost/benefit ratios, BOP systems were largely excluded from regular condition monitoring. The comparatively low cost of MEMS sensors and related IIoT infrastructure now makes a compelling case for expanding MCM (Machine Condition Monitoring) to BOP equipment in order to remain competitive.

CAMP-Engineering has teamed up with SpaceSense to make cutting edge technology for IoT-CBM/IoT-MCM, available to any size industry, priced at a fraction of the cost of traditional alternatives, with significant gains in quality, ease of installation and remote attendance. The major elements of this new system are:

- Sensors

- Communication technology

- Cloud storage

- Remote monitoring, analysis and reporting

Sensors:

CAMP-Engineering has been researching and developing Wi-Fi MEMS accelerometer systems for CBM since 2014, but SpaceSence leaped years ahead with sensors that are attached to Tags by a direct communication cable. This configuration offers significant advantages over alternatives in that the small, lightweight MEMS sensor can readily be located right where needed (e.g. even between electric motor cooling fins), while the Tag takes care of long-range Bluetooth communications and the ADC.

While a myriad of different capability MEMS accelerometers are available, in its “standard” configuration, the sensor is a +-40g triaxial accelerometer with on-board temperature sensor, with Fmax = 1950Hz and Fmin = 3Hz, offering 11,700 lines of resolution to enable a frequency resolution of about 0.2Hz.

Available Precision, High Resolution Sensor Types include: Vibration, Contact Temperature, Tachometer, and Fluid Pressure

Communication Technology:

The data from any number of sensors are routed through ultra-long range Bluetooth (BLE5) gateways. The X2000 shown (and ATX2000 for hazardous environments) is the most reliable long-range Bluetooth router for demanding indoor or outdoor enterprise Bluetooth IoT applications. It extends Bluetooth’s range up to 1 kilometer and enables remote control of up to 40 Bluetooth Low energy devices (and hundreds in broadcast mode) without requiring changes to the end devices. The X2000 acts as an Internet Gateway in conjunction with SX3’s IoT Access Controller (AC) for easy deployment and management.

The X2000/ATX2000 can be used as a protocol gateway, which translates between Bluetooth protocol and IP

protocol. The X2000 Internet Protocol (IP) backhaul options include Ethernet, 2.4/5GHz Wi-Fi and USB cellular modem.

As a result, end devices are remotely accessible and controllable via an Internet application.

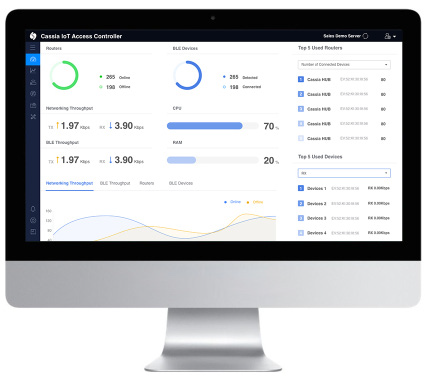

The IoT Access Controller (AC) provides an easy-to-use device management platform. The IoT AC user interface simplifies the deployment and management of thousands of Cassia X2000 gateways and connected end devices.

Cloud Storage:

In its preferred configuration, the CAMP-CBM/MCM system is set up to use AWS Cloud Storage. However, equivalent client preferences that provide 24/7 access to our autonomous remote monitoring, analysis and reporting software, can be accommodated.

Remote Monitoring, Analysis and Reporting:

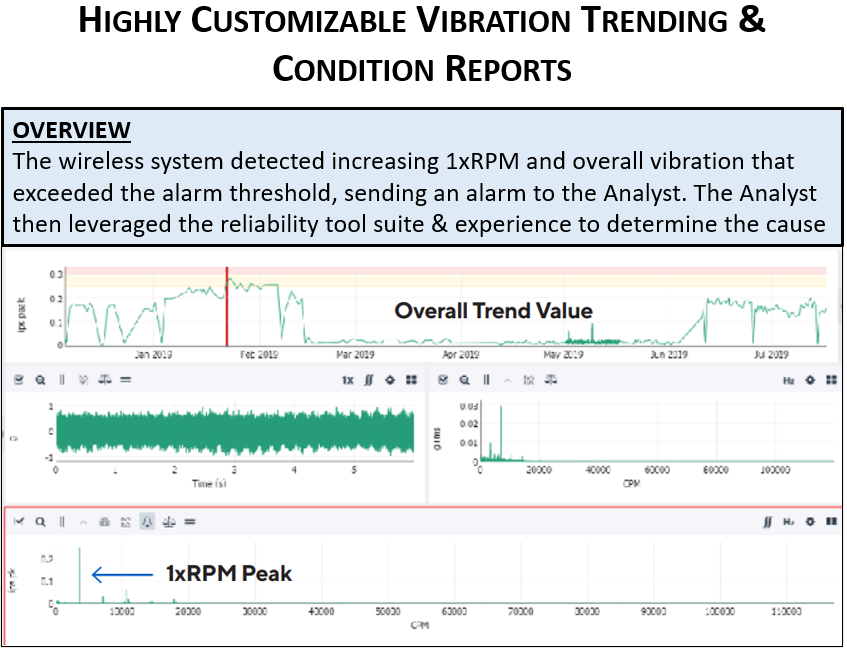

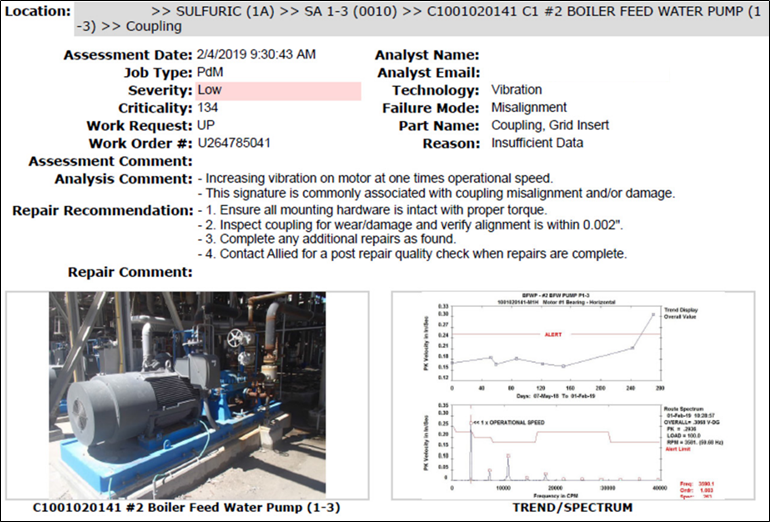

In partnership with SpaceSense and its other affiliates, the CAMP-CBM / CAMP-MCM wireless intelligent condition assessment nodes (i-CANTM) allow highly customizable machine condition and asset condition trending reports. Key to effective and efficient reporting to management is clear, unambiguous communication using familiar and easy identifiable formats. Each client and each management team has their own preferences, but at the heart of reporting, are familiar trend plots with clear alarm levels, vibration wave-forms, FFT spectra, and waterfall plots (if desired) as illustrated below.

Contact CAMP-Engineering today to discuss your needs.